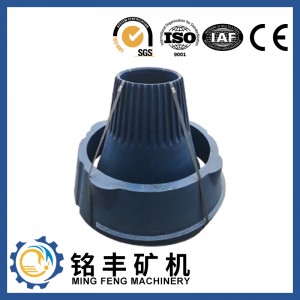

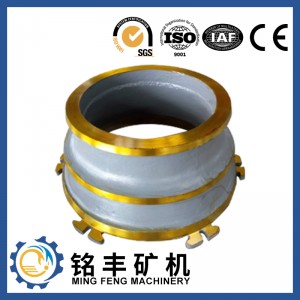

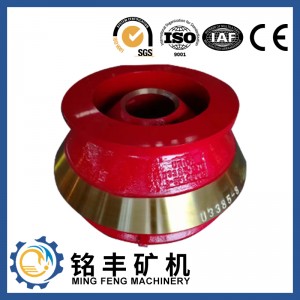

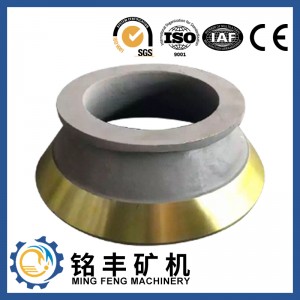

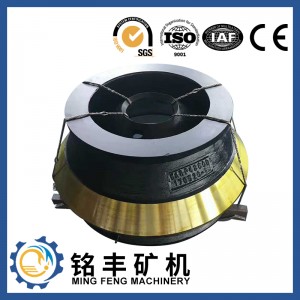

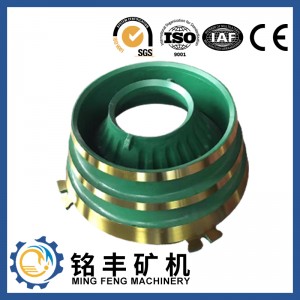

Factory directly wear parts for cone crusher

Overview:

| Type | Bowl Liner, Concave Ring, Cone Liner,Mantle Liner | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | Cone Crusher | Certification | ISO 9001:2008 |

| Hardness | HB220~240 | Production Capability | More than 42000 tons/year |

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Casting Inspection | Direct-reading Spectrum Instrument, Metallographic Analysis, Ultrasonic Inspection, Magnetic Particle Inspection, Mechanical Properties Inspection | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

Description:

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between cone crusher mantle and bowl liner.

We offer cone crusher mantles and bowl liners in 13%, 18% and 22% grades of manganese with chromium ranging from 2%-3%.

Mn13Cr2 Cone Crusher Wear Parts

We use the Mn13Cr2 to cast cone crusher parts. Decrease the content of element “Mn” and”C”,and add more “Cr” element. By use this material,it can make up the shortcomings of the traditional high manganese steel toughness, effectively extending the service life of wear-resistant parts.

Mn18Cr2 Cone Crusher Wear Parts

Using Mn18Cr2 material, the compound metamorphic treatment, grain refinement, purification of grain boundaries; casting solidification control methods to optimize the heat treatment process, casting high hardness, toughness, impact resistance, suitable for large and medium-sized cone crusher jobs

Mn22Cr2 Cone Crusher Wear Parts

We manufacture cone liner for Australia clients by this material,after their feedbacks, it has more span life.

Our company adopts a standardized production process, from production research and development, quality inspection, to after-sales service, there is a complete set of processes to ensure that we can provide our customers with high-quality crusher parts and considerate services. Sticking to the principle of ‘Super High-quality, Satisfactory service’.

Cone Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed