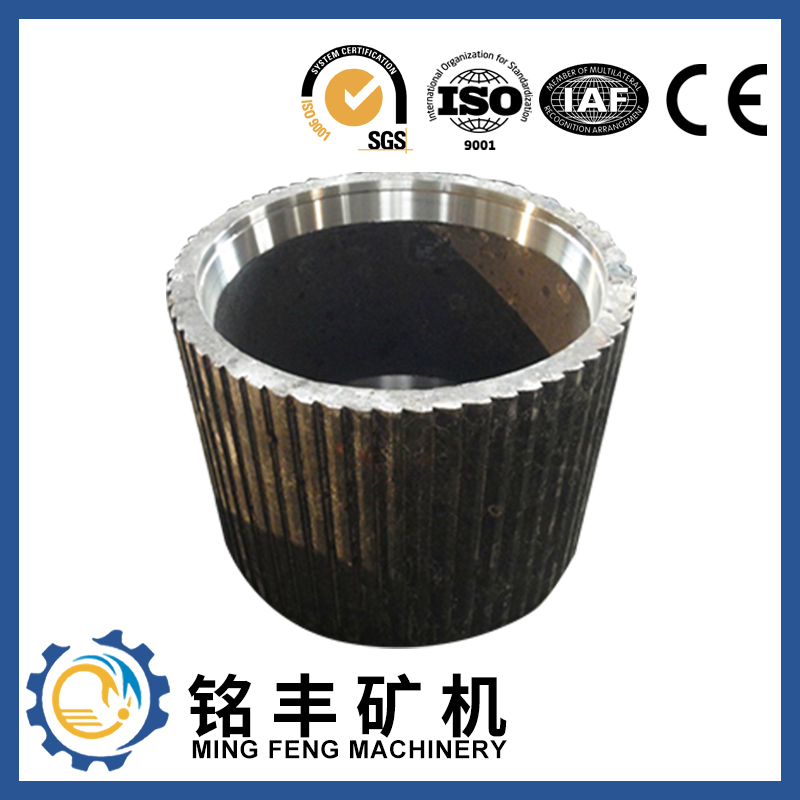

High chrome casting roller crusher wear parts

Overview:

| Type | tooth plate, Double Roller Crusherroller skin, high manganese steel roller skin | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | Roller Crusher | Certification | ISO 9001:2008 |

| Hardness | HRC58 – HRC63 | Production Capability | More than 30000 tons/year |

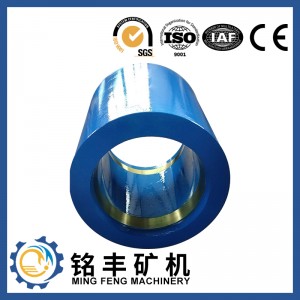

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Production Test | Hardness testing, metallographic testing, spectral analysis, mechanical properties and heat treatment. | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

High chromium compound roll skin

Such roller outer skin made of high-chromium alloy, ductile iron lining, high surface hardness, is mainly used for crushing roller machine used in ceramic tiles scission, coal gangue, shale, brick industrial process tailings fineness checks while rolling through the mixing of raw materials, increased formability, and lower raw material of plastic or clay hollow bricks high porosity needed raw materials for fine processing applications. Select the device should be equipped with a roll grinder ring to ensure proper function and play its role.

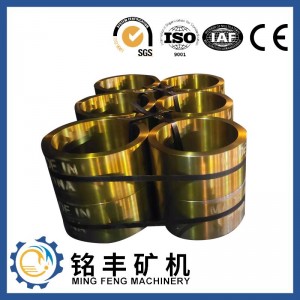

The characteristics of High chromium cast iron roller by centrifugal casting.

1. Using bi-metal composite centrifugal casting technology.

2. The centrifugal casting without pores and inclusions by using centrifugal force.

3. Fast cooling metal mold making the casting have a compact microstructure to improve wear resistance.

4. Using high chromium cast iron(Cr17NiMo,Cr18Ni2,etc) to the out layer of roller, using alloy ductile iron like GGG400 etc or alloy steel like 35CrNiMo etc at inner layer (with high strength and toughness).

5. By reasonable wear resistant layer thickness design according to client’s requirement to reduce the dosage of alloy and the cost.

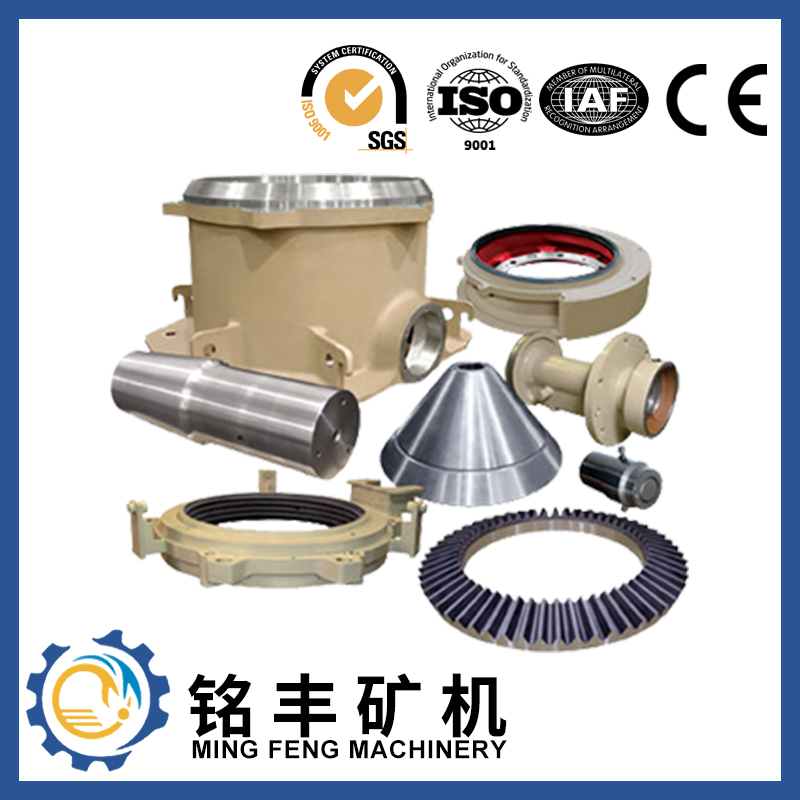

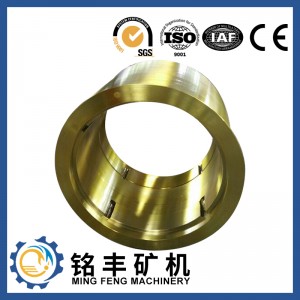

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Don’t have the model you need?

Don’t have the model you need?

We work with technical drawings for any non-standard products. If the order is for standard parts,you only have to provide us with the part number so we may define the parts of the order.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed