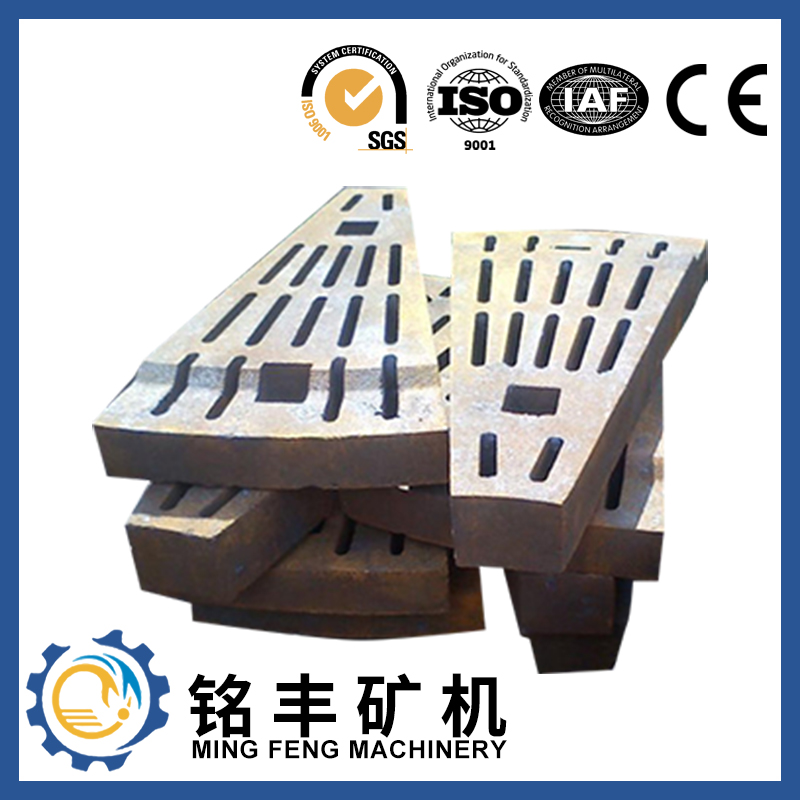

High manganese ball mill lining plate

Overview:

| Type | Crusher liner board, lining plate | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Grinding ores | Quartz, Gold ore, Cement clinker, etc. |

| Machine Type | Ball Mill Liner | Certification | ISO 9001:2008 |

| Main Materials | Mn13Cr2 , Mn18Cr2, Mn22Cr2, Cr22, Cr26 | ||

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Casting Inspection | Direct-reading Spectrum Instrument, Metallographic Analysis, Ultrasonic Inspection, Magnetic Particle Inspection, Mechanical Properties Inspection | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

Description:

First of all, the liner is a protruding piece in the inside of the crusher. Because the equipment is a consumable equipment, that is, when working, the internal parts will gradually wear out as the working time increases. When the wear reaches a certain level At a certain level, the equipment can no longer work smoothly, and the liner can play a protective role inside the equipment, reducing the wear or damage of some parts inside the crusher, which can reduce the impact on the efficiency of the equipment. Reduce the cost of parts maintenance.

Secondly, the lining board can improve the efficiency and productivity of the crusher, because the lining board generally has saw teeth. When the equipment is crushing materials, the saw teeth can effectively crush the materials, and the effect is very obvious, but this effect will make the saw teeth and There is friction between materials, which makes the saw teeth gradually wear and lose their effect. Therefore, better steel plates can be used to process the liner to improve its own hardness and wear resistance. This is also better for the improvement of equipment working strength and productivity. Great help.

Casting Material Chemical Composition:

| High Manganess Casting Material Chemical Composition | |||||||

| Code Elem. | C | Mn | Si | Cr | Mo | P | S |

| ZGMn13-1 | 1.0-1.45 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-2 | 0.90-1.35 | 11.0-14.0 | 0.30-1.0 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-3 | 0.9-1.35 | 11.0-14.0 | 0.30-0.8 | - | - | ≤0.09 | ≤0.04 |

| ZGMn13-4 | 0.9-1.30 | 11.0-14.0 | 0.30-0.8 | 1.50-2.0 | - | ≤0.09 | ≤0.04 |

| ZGMn13-5 | 0.75-1.30 | 11.0-14.0 | 0.30-1.0 | - | 0.90-1.2 | ≤0.09 | ≤0.04 |

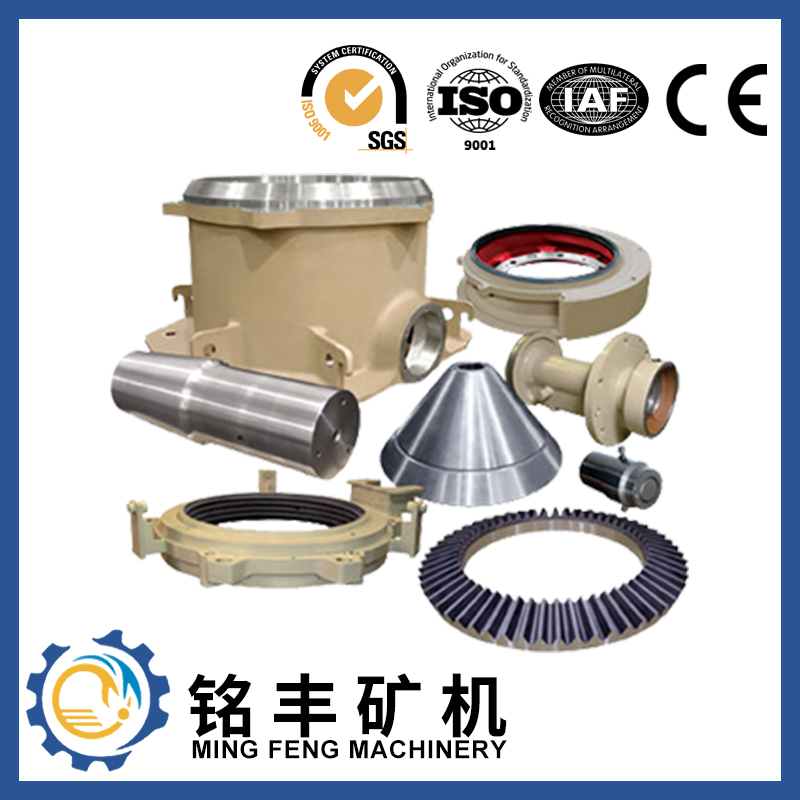

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Quality First, Safety Guaranteed