High manganese steel NP15 blow bar for impact crusher

Overview:

| Type | Bowl bar | ||

| Main Model |

NP series | NP1313,NP1415,NP1620,NP2023,NP1110,NP13,NP15,NP20 | |

| Origin | China | HS Code | 84749000 |

| Condition | New | Applicable Industries | Energy & Mining |

| Machine Type | Impact Crusher | Certification | ISO 9001:2008 |

| Hardness | HRC58 – HRC63 | Production Capability | More than 10000 tons/year |

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Production Test | Hardness testing, metallographic testing, spectral analysis, mechanical properties and heat treatment. | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

Description:

The amount of chrome mixed into the design of a blow bar determines how well the part can withstand abrasive materials: the more chrome in a blow bar, like in high chrome bars, the more effective it can crush highly abrasive materials, like asphalt. Medium chrome blow bars are valuable for processing a variety of materials while low chrome bars can be useful for crushing aggregate and concrete.

On the other hand, the amount of chrome mixed into a blow bar can also determine how susceptible the blow bar is to fracturing. When crushing reclaimed materials that might include metal contaminates like rebar, high chrome blow bars are more likely to fracture. Meanwhile, low chrome bars are better at withstanding the impact of rebar and other metal contaminants.

As the rotor of a horizontal shaft impact crusher runs and material is fed into the crusher chamber, the material comes into contact with the rapidly spinning blow bars which strike them with a great force over and over. The repeatedly impacted material quickly fractures and reduces in size until it is the appropriate size to be released from the chamber.

Due to the repetitive crushing that blow bars endure, they will wear down over time. Their composition and how often they are used will determine how often they will need flipped or replaced. Stocking fresh blow bars so that material is being impacted by smooth, uniform edges will contribute to maintaining high production rates.

| Chemical Composition: | |||||||

| C% | S% | P% | Si% | Mn% | Cr% | Mo% | Ni% |

| 2.8-3.2 | <0.08 | <0.08 | ≤1.0 | 0.5-1.2 | 27-30 | 0.3-2.5 | 0.5-1.0 |

| Mechanical Property Hardness(HB) | Microstructure | ||||||

| 600-660 | M+C | ||||||

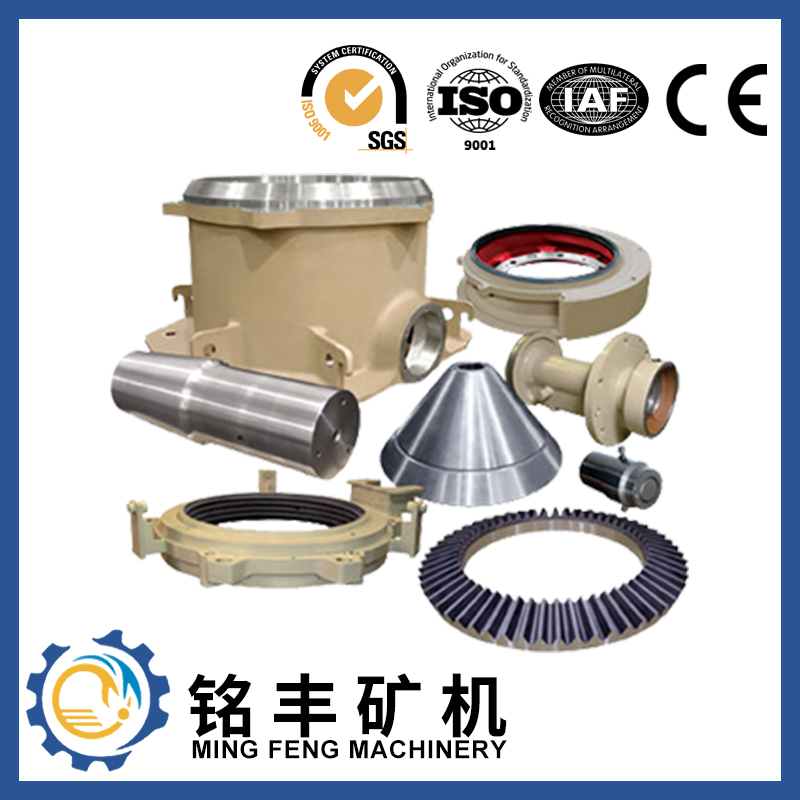

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Quality First, Safety Guaranteed