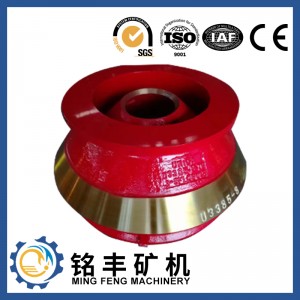

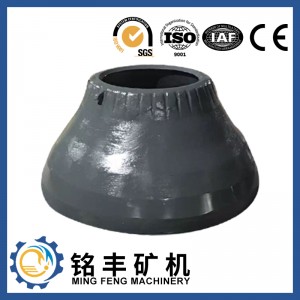

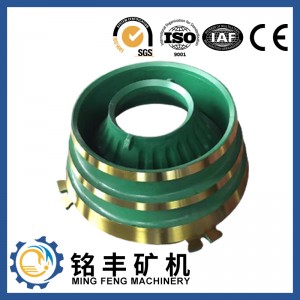

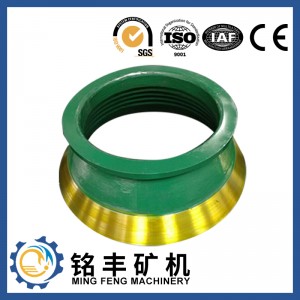

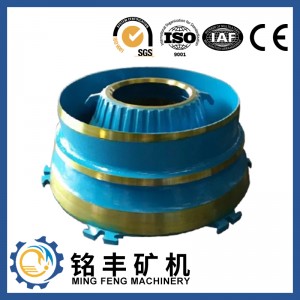

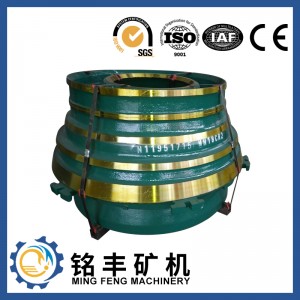

HP500 cone crusher cone liner and bowl liner SH F/M/C

PRODUCT DESCRIPTION:

Ming Feng MACHINERY is a professional manufacturer of HIGH MANGANESE STEEL CASTING PARTS,The products are made of high-quality raw materials, through scientific and reasonable ratio of elements (molybdenum, manganese, rare earth lanthanum, etc.), melting in medium frequency furnace, forming once, and then through a series of heat treatment processes (heat treatment temperature reaches 1045 degrees), the toughness and wear resistance of the products can reach 1.2 to 1.5 times that of similar products.Our products have been widely used in mining, metallurgy, thermal power, cement, sand mining, gold panning and other industries

Specifications

1. HP500 cone crusher cone liner and bowl liner SH F/M/C

2. Durabale Performance

3. Mantle and concave (bowl liner)

4.High Manganese Steel (Mn13Cr2, Mn18Cr2, Mn22Cr2 and customised material)

4. OEM available

5.Lead time:25-35days.

6.Over 30years experience

Advantages:

1.Best quality control promise the high performance.

2.Same life time with same guarantee time as original OEM products.

3.Certified by ISO system certification.

4.Short delivery time,always keep large amount of goods stock for customer.

5.The best price of the solution will save large amount cost for customer.

Chemical Component of concave and bowl liner.

| Material | C | Mn | Cr | Si | Mo | Ni | Cu |

| Mn13Cr2 | 1.0~1.4 | 12~15 | 1.7~2.2 | 0.3~1.0 | - | - | - |

| Mn18Cr2 | 1.0~1.4 | 17~19 | 1.8~2.2 | 0.3~1.0 | - | - | - |

| Cr12 | 2.0~3.3 | ≤2.0 | 11~14 | ≤1.2 | ≤3.0 | ≤2.5 | ≤1.2 |

| Cr15 | 2.0~3.3 | ≤2.0 | 11~14 | ≤1.2 | ≤3.0 | ≤2.5 | ≤1.2 |

| Cr20 | 2.0~3.3 | ≤2.0 | 14~18 | ≤1.2 | ≤3.0 | ≤2.5 | ≤1.2 |

| Cr26 | 2.0~3.3 | ≤2.0 | 23~30 | ≤1.2 | ≤3.0 | ≤2.5 | ≤2.0 |

HOT-SALE PRODUCT

Quality First, Safety Guaranteed