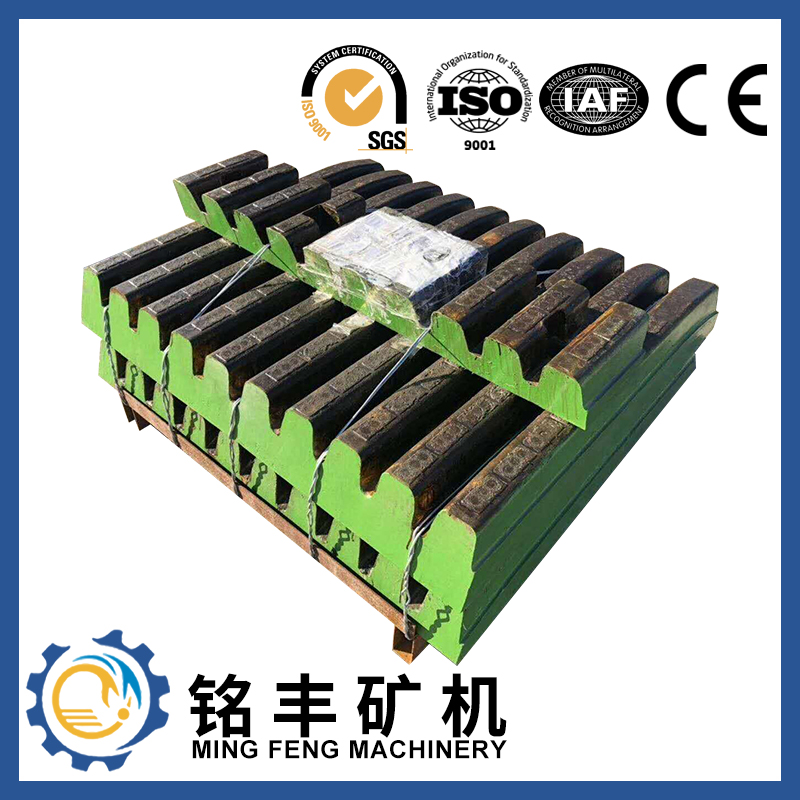

Liming 912 ceramic insert Blow Bar

Description:

MF selects high-Cr cast iron(or martensite steel)ceramic composite materials, which forms the ceramic metal composite reinforcement through injection of ceramic particles into the high-Cr material , the composite layer wear-resisting property is than high Cr material 3-4 times, at the same time, the composite layer thickness can be made to a third of the thickness of the original spare parts. Ceramic composite material blow bar life is longer than 2 times of a high Cr alloy blow bar.

Widely used in mining industry, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone and so on.

Advantages:

1. Strict Casting Standards & Advanced Matrix Composites.

2. Superior solutions for High Wear Resistance and Excellent Impact Resistance.

3. Up to 2 -3 Times Service Life comparing with traditonal high chrome steel.

4. Lower Operating Costs and good choices for many applications.

Crusher Parts:

We have precision machined replacement crusher spare parts including jaw plate, jaw plate wedge, pitman, main frame, pulley, upper side plate, lower side plate,toggle plate and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1. 30 years of manufacturing experience, 6 years of foreign trade experience

2. Strict quality control, Own laboratory

3. ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Quality First, Safety Guaranteed