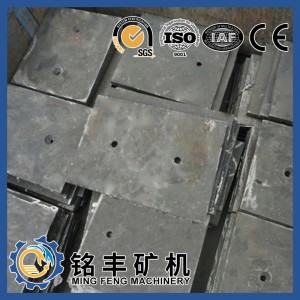

Mill liner/segment plate for cement companies

Overview:

| Type | Crusher liner board, lining plate | ||

| Origin | China | HS Code | 84749000 |

| Condition | New | Grinding ores | Quartz, Gold ore, Cement clinker, etc. |

| Machine Type | Ball Mill Liner | Certification | ISO 9001:2008 |

| Main Materials | Mn13Cr2 , Mn18Cr2, Mn22Cr2, Cr22, Cr26 | ||

| Processing Type | Casting | Surface Treatment | Polishing/Spray-Paint |

| Casting Inspection | Direct-reading Spectrum Instrument, Metallographic Analysis, Ultrasonic Inspection, Magnetic Particle Inspection, Mechanical Properties Inspection | ||

| Transport Package | Packed in Pallet/Case | Guarantee | Same as Original |

| Quality | High Level | Experience | Over 30 Years |

Performance Comparison:

| HMCB04 Chromium-molybdenum Steel | Common Chromium-molybdenum Steel | |

| Hardness | HB 350-400 | HB350-375 |

| Impact Value | ≥80J | ≥45J |

| Tensile Strength | ≥1300J | ≥1200J |

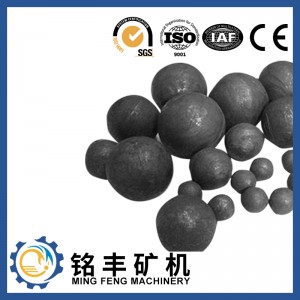

Ball mill is the key equipment for crushing materials after crushing. It is widely used in the production industries of cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal beneficiation, and glass ceramics. It is used for dry or wet grinding of various ores and other grindable materials.

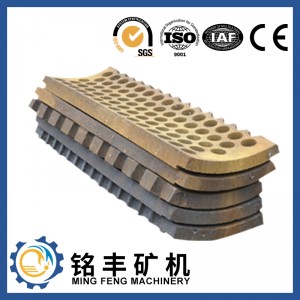

Ball mill liner classification

Ball mill liners are generally divided into five categories according to their use parts: cylinder liner, grinding head liner, partition board, grinding grate board, manhole liner and special liner. Special liner refers to components with special functions, such as retaining ring, ring, etc., although it is no longer a protective part in the traditional sense, we still call it a liner, and are classified as a special liner. class.

Ball mill liner material

The liner material has developed from early high manganese steel, nickel hard cast iron, ordinary white cast iron, etc. to today’s several series of hundreds of varieties, mainly alloy steel, high and low chromium cast iron, austempered ductile iron and other materials. A flourishing situation in China.

Ball mill liner shape

Its shape is no longer a simple plate shape, corner spiral, rounded square liner, groove liner, its many forms and complex shapes, there are too many to mention. So in production practice, the specific material and structure of the lining board should be selected according to the specific working conditions.

Advantages:

Of longer service life

Of higher hardness

Of better property of impact value and tensile strength

Of higher hardenability

Widely used and commonly accepted

OEM and ODM are available.

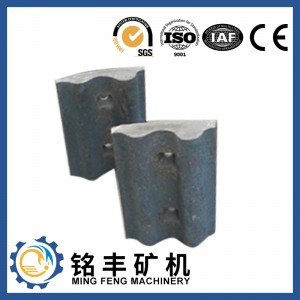

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Quality First, Safety Guaranteed