News

-

Characteristics of LT120E jaw type mobile crusher

Lokotrack LT120E jaw crusher (mobile) has good economy energy, a set of equipment has a variety of features. C120 jaw crusher with high inertia of the flywheel can achieve balance breaking operation, while Caterpillar C13 inline 4 cylinder engine and generator to speed stable operation of 1500rpm...Read more -

C series jaw crusher features

Its C series jaw crusher is quarrying, mining, gravel pit, and even recycling such ideal ground fixed crushing equipment. They are easy to install, powerful performance, high productivity, and can be applied to existing equipment renewal or new crushing crushing station. Because of its C series...Read more -

Lokotrack LT100C and Lokotrack LT120 mobile jaw crusher

Lokotrack LT100C type crusher has two feeder arrangement models. The need for effective pre screening of large quantities of fine-grained application, can provide a combined type plate feeder and equipped with independent double screening machine. According to the selected feeding system, track t...Read more -

Test run of GP200 cone crusher

1. cone crusher before starting to check the main connection fastening, the eccentric sleeve to rotate at least 2-3 circle with the hand rotation of the machine. Be flexible. No jamming phenomenon, can drive . 2. Before the start, should start pump. The lubricating oil obtained until all lubricat...Read more -

Mobile jaw crusher -LT100

Its Lokotrack type LT100C type C100 type jaw crusher with famous crusher as the core component, the feeding port specifications (mm * mm) 1100 x 850. The power source of the crusher is a C13 type low emission diesel engine with a power of 310kW. The quality of the crusher is 58000kg. Lokotrack LT...Read more -

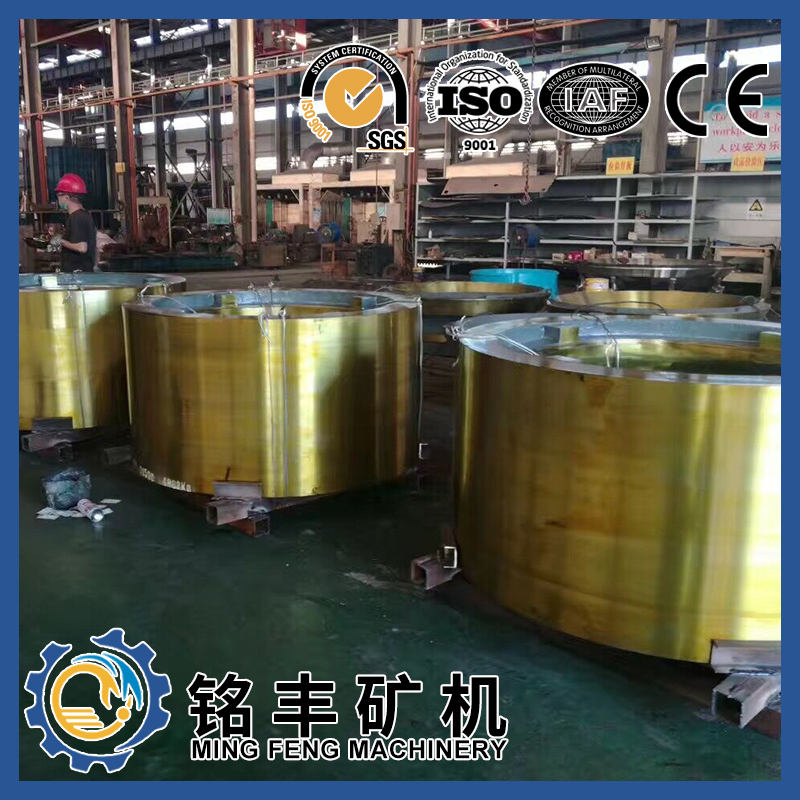

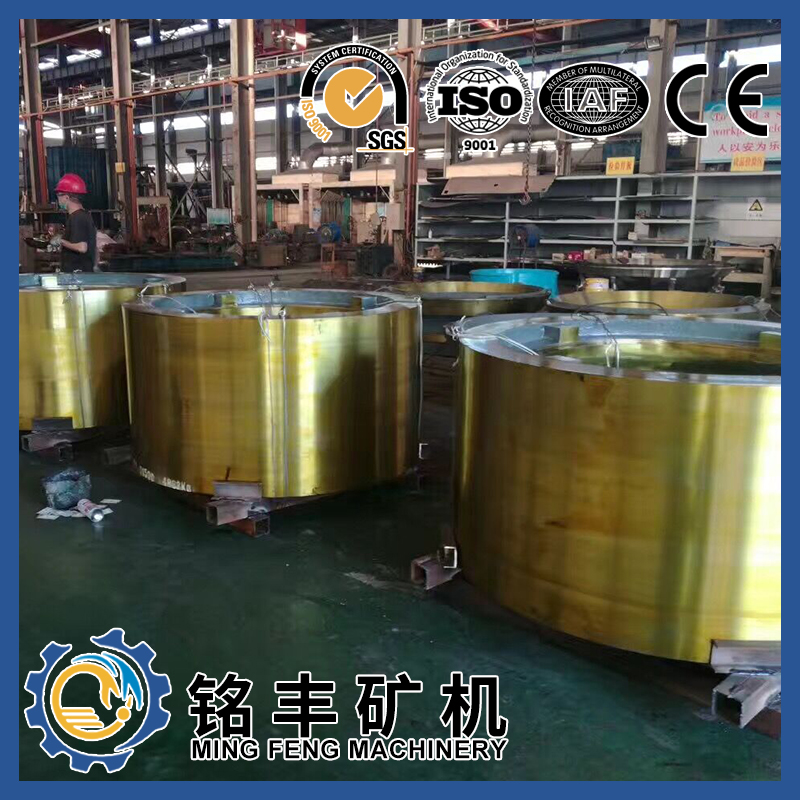

Simmons cone crusher CS series

Structure composition: CS series cone crusher is mainly composed of a machine frame, a fixed cone assembly, movable cone assembly, spring mechanism, bowl shaped shaft frame and transmission parts. The auxiliary part by electrical system, oil lubrication system, and the hydraulic cavity cleaning s...Read more -

Features of CS Simmons cone crusher

1. High performance: through the optimization design of cavity and the combination of reasonable speed and stroke, this machine can do the most work under the same moving cone diameter. Therefore, compared with the same type of spring cone crusher, it has higher performance and production capacit...Read more -

Simmons cone crusher PYS series

Simmons cone crusher is a new cone crusher (PY spring cone crusher) developed on the basis of the introduction and absorption of American Simmons cone crusher Technology.In comparison, in the machine production capacity, PYS Simmons cone crushing product size, product shape, weight of equipment, ...Read more -

How to reduce the Wear of Roller Crusher

The main factors that affect the wear of roller skin include the hardness and particle size of the broken material, the material of the roller skin, the size and surface shape of the roller, the way of ore feeding, and so on. In response to these factors, the correct approach is to: (1) the mate...Read more -

Advantages of Sand making with Roller Crusher

According to the working principle of twin roll crusher: wedge or gasket adjusting device is arranged between the two rollers, the top wedge device with adjusting bolt, the adjusting bolt when the wedge pulled up when the wedge will roll from the top fixed round of activities, namely two rollwhee...Read more -

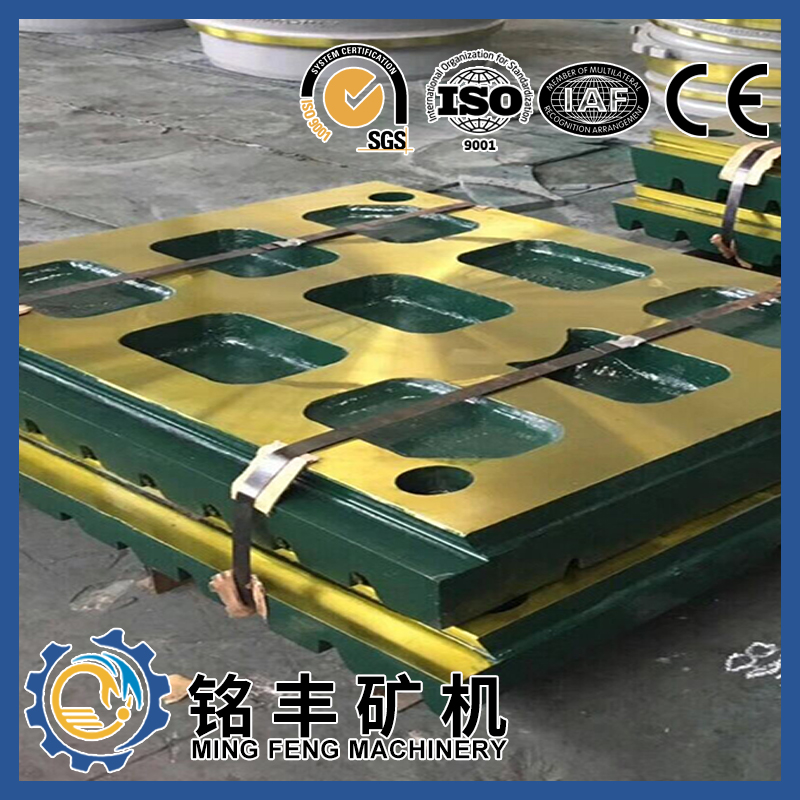

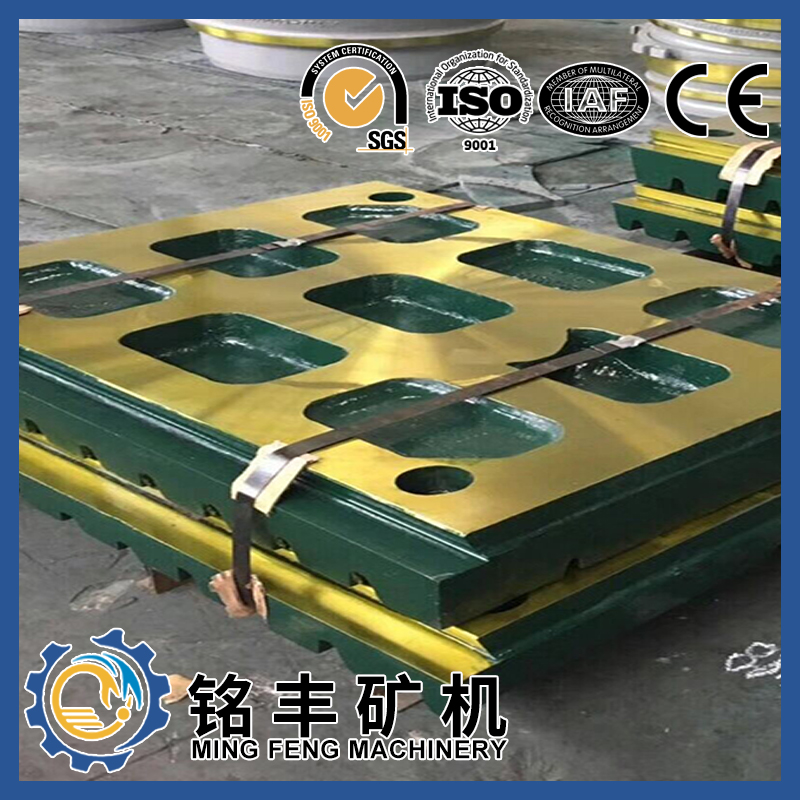

Advantage of TRIO jaw Crusher CT Series products

The jaw crusher requires very high wear resistance, and the material is generally made of high wear resistant manganese steel lining plate. When the High wear resistant manganese steel lining plate, inside its crushing chamber two jaw plates (manganese steel), a jaw plate is fixed (also called a ...Read more -

How to use and maintain double toothed roller crusher better?

First, the use of double toothed roller crusher After the double toothed roller crusher is put into use, in order to ensure the safe operation and make full use of its best performance, it must be regularly maintained according to the requirements and form a system 1, the crusher must be started ...Read more