The main factors that affect the wear of roller skin include the hardness and particle size of the broken material, the material of the roller skin, the size and surface shape of the roller, the way of ore feeding, and so on.

In response to these factors, the correct approach is to:

(1) the material distribution is as uniform as possible in order to reduce the wear degree of ring groove and roller skin on the surface of roller;

(2) in the operation of the crusher, especially in the coarse crushing process, attention should be paid to the size of the ore feeding block to prevent the ore feeding block from being too large, resulting in the severe vibration of the crusher and the serious wear of the roller skin;

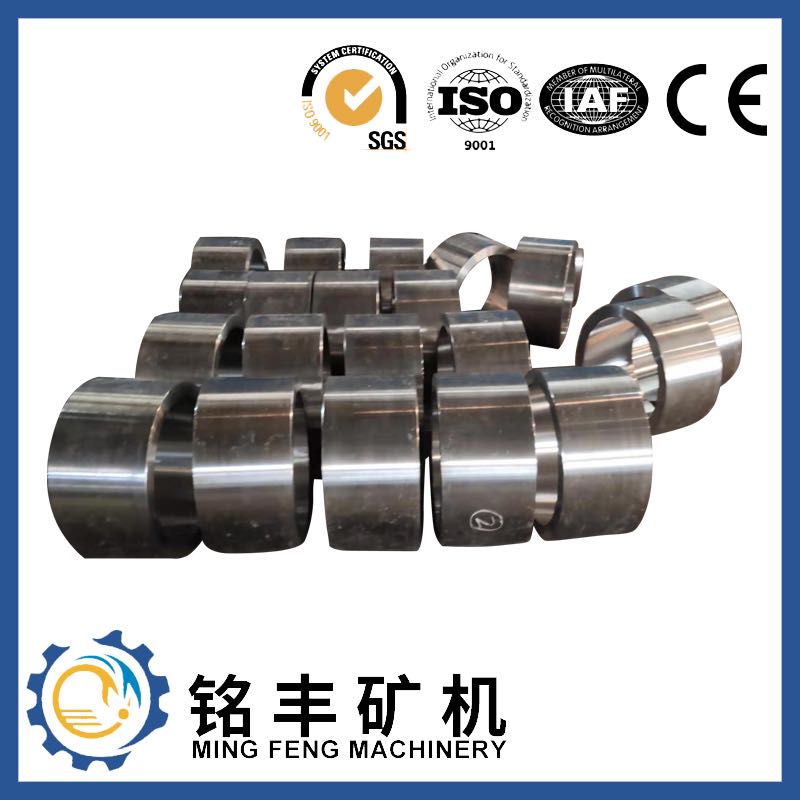

(3) selecting the roller with good wear resistance can reduce the wear degree of the roller and prolong the service life of the roller;

(4) the length of the feeder should be consistent with the length of the roller so as to ensure that the ore is fed evenly along the roller length. In addition, in order to carry out continuous ore feeding, the speed of the feeder should be 1-3 times faster than the speed of the stick;

(5) the particle size of the broken product should be checked frequently, and one of the rollers should be moved once along the axis within a certain time, and the distance of movement is about one third of the grain size of the ore.

In addition, pay attention to the lubrication of the roller, and need to have a check hole in the safety cover, easy to observe the wear of roller skin.

Post time: Aug-05-2022