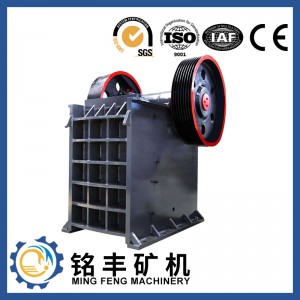

PC-400×300 hammer crusher

Hammer Crusher Technical Data:

|

Model |

Speed |

Feed size |

Selected size |

Output |

Weight |

Power |

Overall Dimensions |

|

PC-400×300 |

1450 |

≤100 |

10 |

3-10 |

0.8 |

11 |

812×9827×85 |

Description:

A hammer mill is a rock crusher used in various industries to reduce the material size, such as limestone, coal, slags, gypsum, glass. It uses of high-speed rotary hammer to impact the ore, the finished product size is adjustable by controlling the grate openings, rotor speed, hammer capacity, etc. Hammer mill, same as hammer crusher, hammer breaker, can crush the 600-1800mm materials to below 25 or 25 mm. Sometimes, the hammer mill crusher is named by the application fields, such as coal crusher, coke crusher, limestone hammer crusher, brick crusher, cement hammer crusher, etc.

Working Principle:

The crusher uses impact to crush materials. During operation, the motor drives the roller to rotate at a high speed. When the material is fed into the chamber, the hammer which is rotating at a high speed hits and cuts the material. In the meantime, because of gravity, the material at a high speed hits with the guard board and the plate. Material that can get through holes on the screen will be discharged while the rest will remain in the chamber for further crushing.

High Grinding Capability:

- Coarse particle in the product is reduced by many numbers of grinding path liners.

- Fine particle in the product is reduced by low fan effect of zigzag hammer alignment.

Easy Maintenance:

- Multi-sectional welded housing allows easy access to every partition and quick exchange of wear parts.

- Hammners are always operated with sharp edges. And high utilization of hammer head with continuous operation is achieved by reversible rotation.

- No cleaning in the grinding chamber is required because hammer head with zigzag hammer alignment cleans the grinding chamber automatically.

Advantages:

1.Easy adjustment of product size

2.High grinding capability

3.Easy maintenance, a quick exchange of wear parts

4.Stable operation

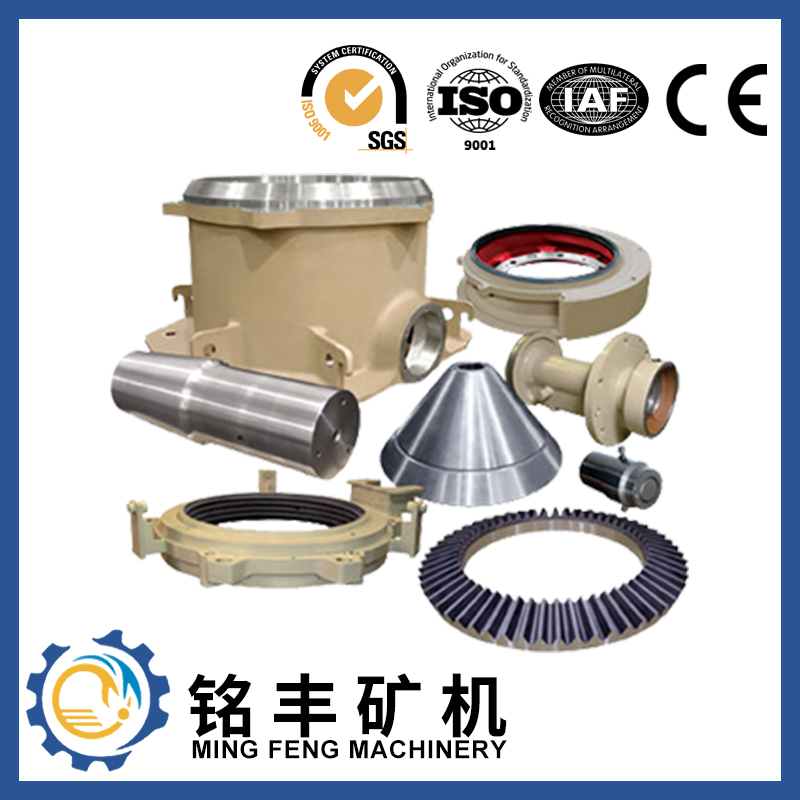

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Quality First, Safety Guaranteed