Super Purchasing for 2449 Wear Parts - 2PG-610X400 roll crusher – MING FENG MACHINERY

Super Purchasing for 2449 Wear Parts - 2PG-610X400 roll crusher – MING FENG MACHINERY Detail:

|

Specification |

Max Feed Edge |

Discharge Size |

Production |

Power |

Weight |

|

2PG-610X400 |

≤40 |

1–20 |

13-35 |

30 |

4500 |

Description:

A type of secondary or reduction crusher consisting of a heavy frame on which two rolls are mounted. These are driven so that they rotate toward one another. Rock fed in from above is nipped between the moving rolls, crushed, and discharged at the bottom.

It is widely used in fields of cement making, chemical engineering, waterpower, metallurgy, construction, fire-proof material making, etc. It is suitable to deal with medium-hardness materials like limestone, pebble, clinker, coke, etc. The material to be crushed should have fracture strength less than 300MPa and humidity less than 35%.

Working principle:

Whether the application requires a single-stage or two-stage crusher, the forces necessary to perform the crushing remain the same: a combination of impact, shear and compression. The impact force occurs as the material enters the crusher and is impacted by the rotating roll. Shear and compression forces occur as the feed material is pulled between the crushing plate and/or crushing rolls.

Depending on the feed size, material is fed into the crushing chamber and encounters a single or a pair of rotating rolls. If a two-stage reduction is required, either a Triple or Quad Roll configuration can be used. In this scenario, the top stage of the crusher performs the primary reduction either by crushing the material between the roll and crushing plate or between a pair of rolls. The material is then fed directly between the two bottom-stage rolls for additional processing.

If a single-stage reduction is required, then depending on the feed-to-product-size ratio of reduction, either a Single or Double Roll Crusher can be selected. Regardless of the crusher type selected, Roll Crushers allow for the material to fracture along naturally occurring cleavage lines, which helps with minimizing fines generation.

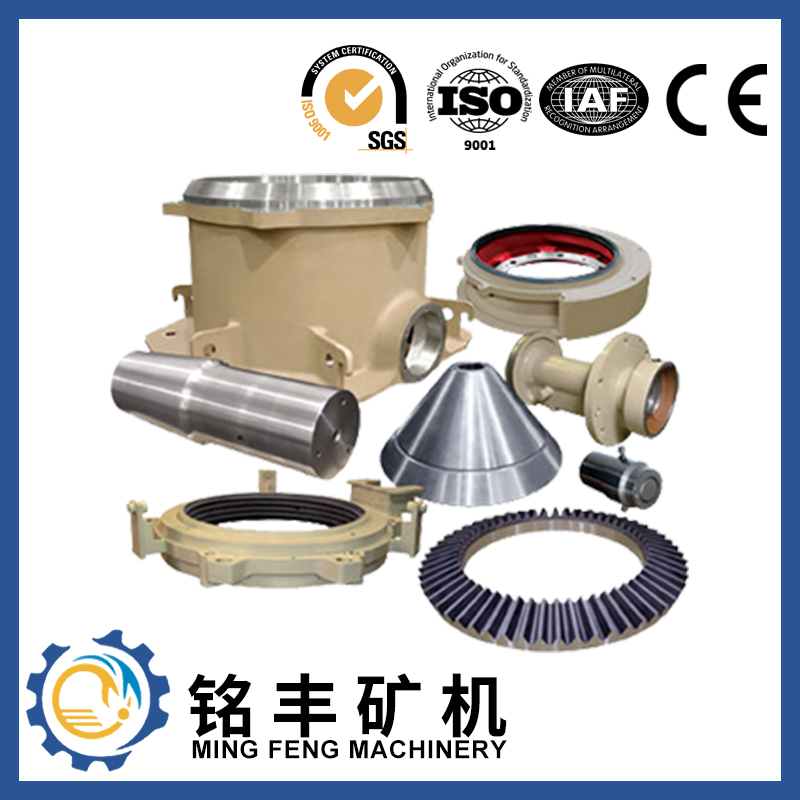

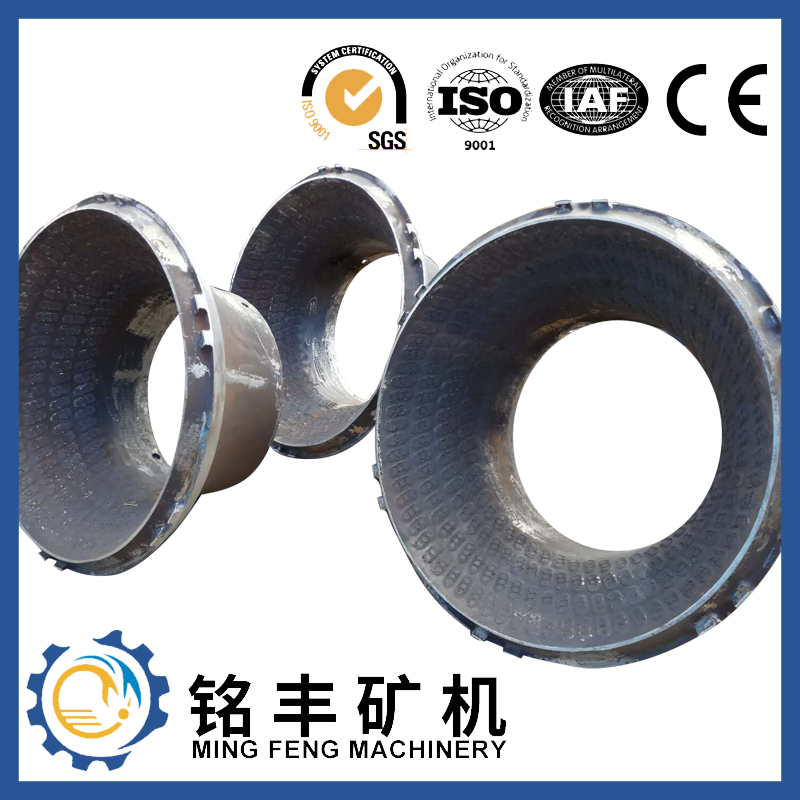

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

The business keeps to the operation concept "scientific management, premium quality and efficiency primacy, customer supreme for Super Purchasing for 2449 Wear Parts - 2PG-610X400 roll crusher – MING FENG MACHINERY , The product will supply to all over the world, such as: United States, Zurich, St. Petersburg, We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

HOT-SALE PRODUCT

Quality First, Safety Guaranteed