Manufacturer for Mn22% Mantle - Mn18Cr2 ceramic particles composite fixed jaw/movable jaw – MING FENG MACHINERY

Manufacturer for Mn22% Mantle - Mn18Cr2 ceramic particles composite fixed jaw/movable jaw – MING FENG MACHINERY Detail:

Description:

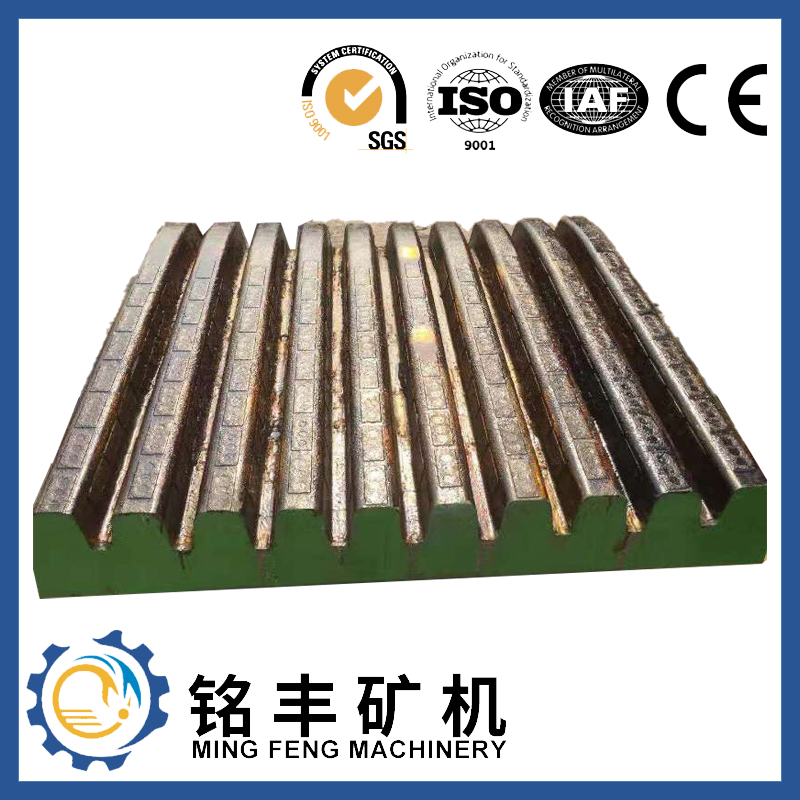

Jaw crusher is widely used high manganese steel manufacturing . Due to the material erosion, theextrusionprocess broken, grinding effect, cause plate wear serious, in order to solve this situation, MF chooses high manganese steel as base material of the ceramic composite materials, which is plate basement with high manganese steel and then embed the high wear resistance With stiffener into the basement.below keeping original work hardening of high manganese steel impact resistance performance and improving wear resistance strength at the same time, the life of the ceramic composite plate is about 2 times longer than the high manganese steel basement plate.

Jaw crusher is mainly used for medium-sized crushing of various ores and bulk materials, widely used in mining, metallurgy, building materials, roads, railways, water conservancy and chemical industries. The highest crushing material is 320MPa. Jaw crusher parts can also be referred to as jaw crusher wear parts, is an important part of the jaw crusher; We can provide various types of jaw crusher wear parts, such as fixed jaw plate, movable jaw plate, toggle plate, liner plate, but also according to the drawings provided by customers to create different materials products.

Advantages:

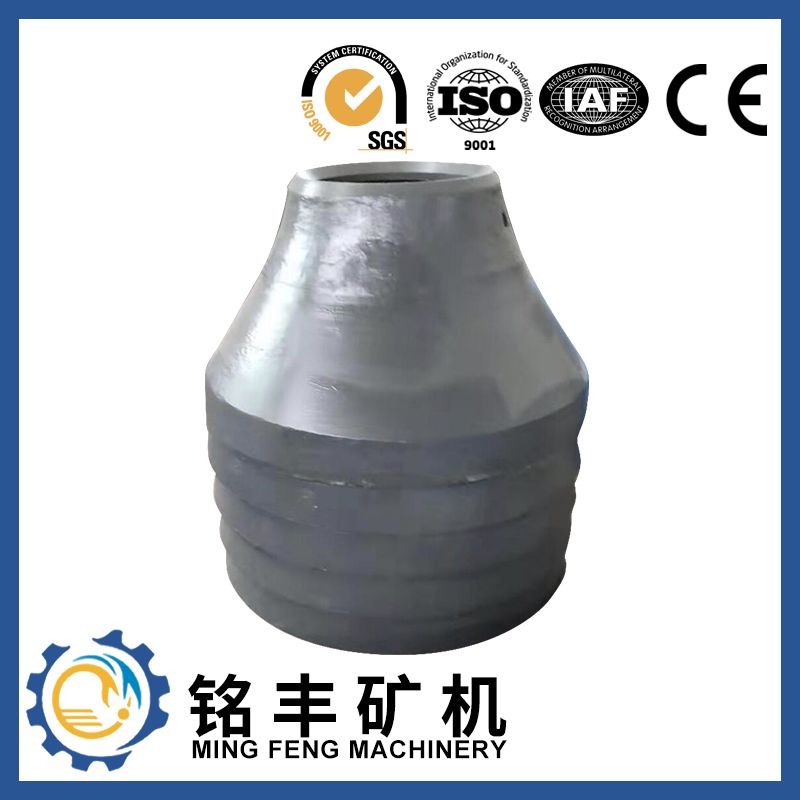

1. Increased Wear Life – MGS Casting’s unique TiC insert cone liners and bowl liners design features a strengthened high-wear zone for maximum usable wear life and reduced breakage.

2. Strengthens as It Works – Concaves and mantles body are cast in durable manganese steel (Mn18Cr2) that gets harder the longer you work it.

3. Consistent Wear – More consistent wear profile for uniform product output and increased efficiency.

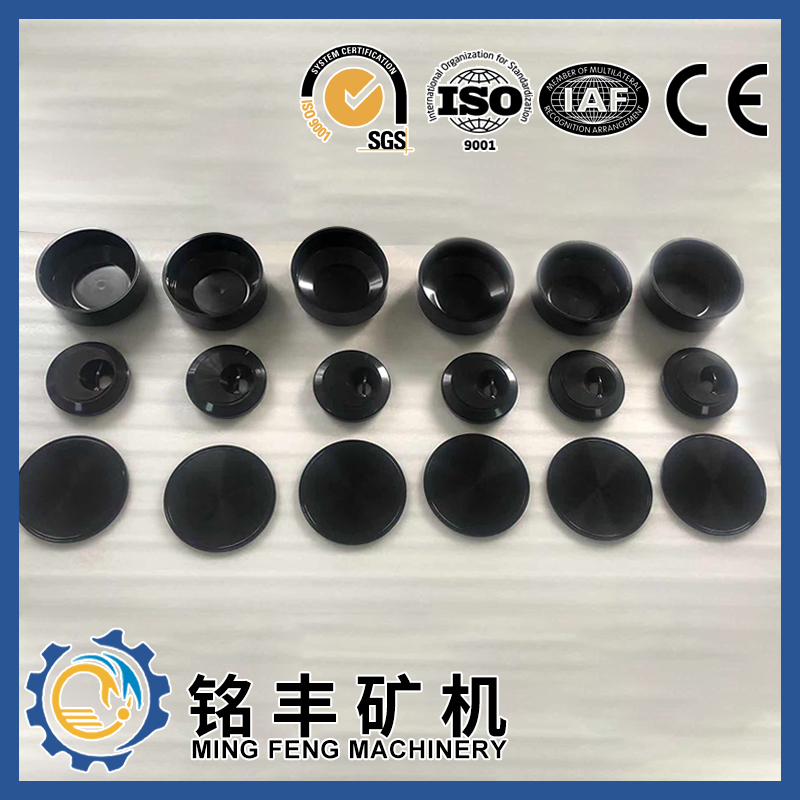

4. Titanium Carbides – TiC inserts currently available are 20mm, 40mm, 60mm, and 80mm depths.

5. Fewer Change-Outs – Greater durability and longer wear life means fewer change outs, more up-time, and lower maintenance costs

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

Along with the Client-Oriented small business philosophy, a rigorous high-quality handle system, highly developed producing machines and a powerful R&D group, we always supply high-quality products and solutions, fantastic services and aggressive costs for Manufacturer for Mn22% Mantle - Mn18Cr2 ceramic particles composite fixed jaw/movable jaw – MING FENG MACHINERY , The product will supply to all over the world, such as: Albania, Ecuador, Marseille, We now have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we've been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed