Manufacturing Companies for Jaw Crusher Parts - DVSI 600 sand-making machine – MING FENG MACHINERY

Manufacturing Companies for Jaw Crusher Parts - DVSI 600 sand-making machine – MING FENG MACHINERY Detail:

|

Model |

Max.feed size |

Rotor diameter |

Speed |

Capacity |

Power |

Weight |

Overall Dimension |

|

40 |

610 |

1600 |

120 |

160 |

6500 |

3670×1821×2100 |

Description:

The DVSI machine is used to make sand from river pebbles, stones, tailings, stone crumbs, etc. It can also be used to crush materials in construction, metallurgy, chemical, mining, fire-resistant materials, cement, abrasive materials industries. The machine is famous for its low power consumption and large productivity. The design and the angle by which materials are thrown have been optimized. The patent self-circulating wind system of the machine improves efficiency.

Working Principle:

The crushing has applied the mechanism “rock on rock” and the friction between materials. As a result, sizes of material must be in accordance with technical parameters. In addition, the maximum humidity should be under 20%. The smaller the material is, the smaller the finished products are or vice versa.

The size of the finished products can be changed by adjusting the speed of the impeller. The percentage of pass is up to 60% if the size of the finished products is less than 10mm.

Advantages:

1.Energy-saving

2.High productivity

3.Simple structure

4.Durable and cost-effective

5.Oil with low viscosity is used as the lubricant.

6.Parts are very easy to replace.

7.High pack density

8.Reduced dust level.

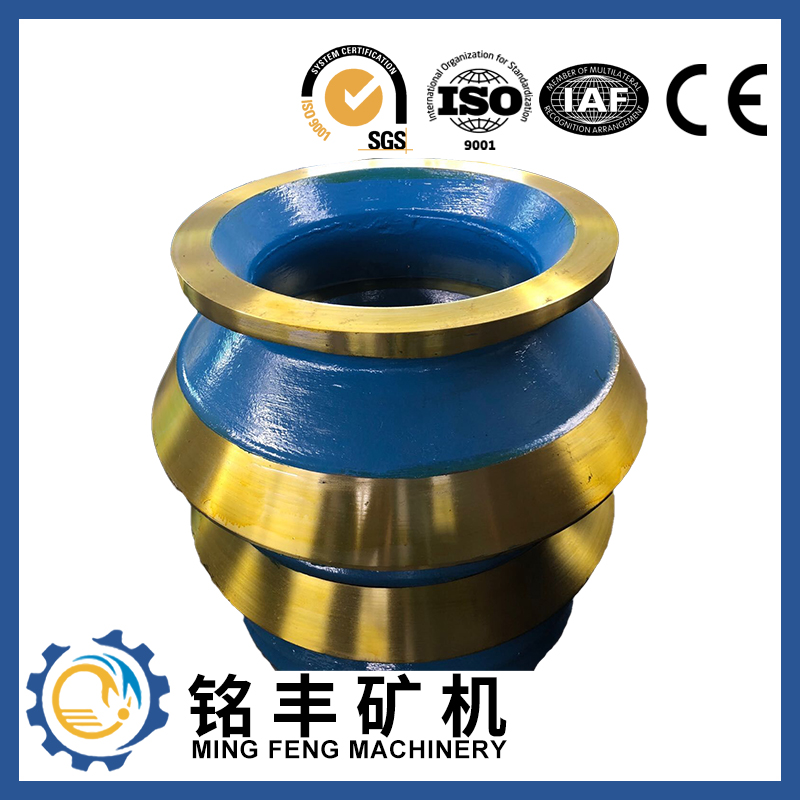

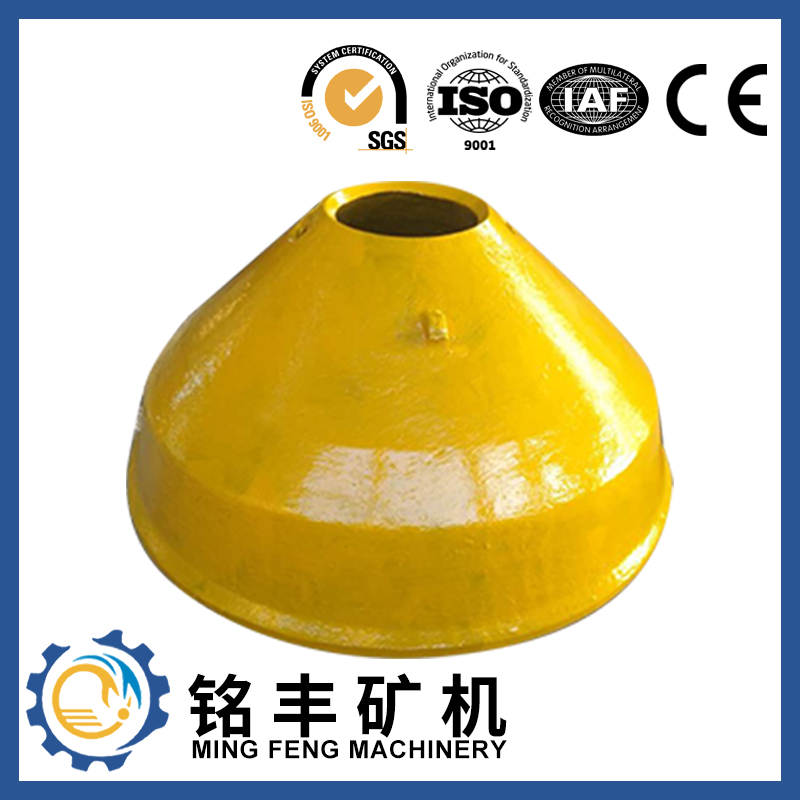

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1.30 years of manufacturing experience, 6 years of foreign trade experience

2.Strict quality control, Own laboratory

3.ISO9001:2008, BUREAU VERITAS

Product detail pictures:

Related Product Guide:

We are going to dedicate ourselves to providing our esteemed buyers together with the most enthusiastically thoughtful products and services for Manufacturing Companies for Jaw Crusher Parts - DVSI 600 sand-making machine – MING FENG MACHINERY , The product will supply to all over the world, such as: New Zealand, Romania, Sao Paulo, Our objective is to supply first step products and best service for our customers, thus we are sure you must have a margin benefit through cooperating with us. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed