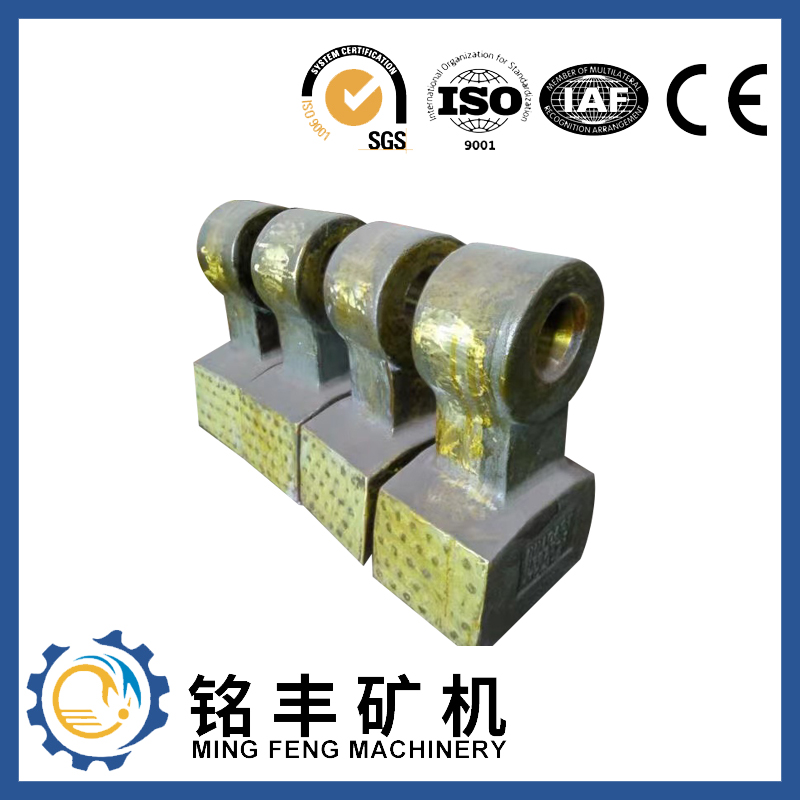

40 mm TiC hammers

Description:

40 mm TiC Hammers Last 2.5 Times Longer Than normal hammers

MF innovative titanium carbide hammer inserts result in less frequent hammer replacements and significant cost savings.

Most high-impact applications in the mining and cement industries show that there is not only wear from impact but also high sliding wear.

Traditional solutions tend to solve one problem or the other but not both. On the one hand, a high chrome weld on a cast manganese hammer performs well in high sliding situations, but high chrome can break under high impact. On the other hand, manganese thrives in high impact situations but quickly fails in high sliding applications if it does not have an opportunity to work-harden. Titanium carbide (TiC) inserts in a manganese alloy allow the manganese to work-harden before extensive wear occurs and, as such, solve the issue of wear due to both high sliding and high impact.

Crusher Parts:

We have precision machined replacement crusher spare parts including head, bowls, main shaft, socket liner, socket, eccentric bushing, head bushings, gear, countershaft, countershaft bushing, countershaft housing, mainframe seat liner and more, we can support your entire machine for mechanical spare parts.

Why choose us?

1. 30 years of manufacturing experience, 6 years of foreign trade experience

2. Strict quality control, Own laboratory

3. ISO9001:2008, BUREAU VERITAS

HOT-SALE PRODUCT

Quality First, Safety Guaranteed