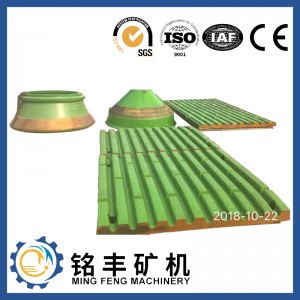

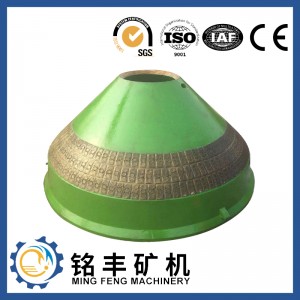

MMC mantle- ceramic insert mantle

Description:

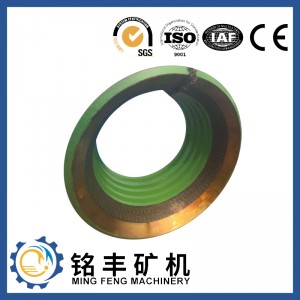

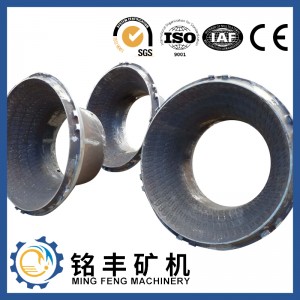

When Cone crusher works, eccentric sleeve rotates by motor through V-belt, big pulley, drive shaft, a small bevel gear, big bevel gear. crushing cone axis rotates and swing under the pressure of eccentric sleeve, make the cone sometime close to the mantle and sometimes far from it, so that the material in the ring fixed cone and fixed cone crushing cavity composed constantly under attack, squeezing and bending and breaking. After several extrusion, impact and bending, the material is crushed to the required size, and discharged from the lower part.

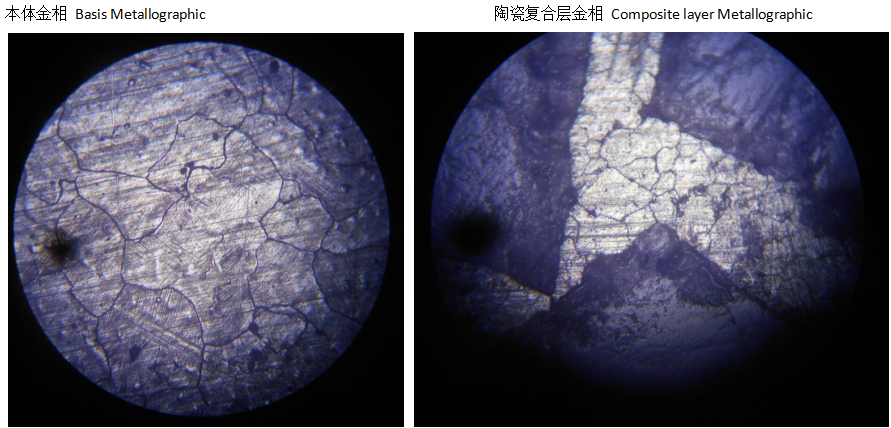

MF choose high manganese steel as metal matrix, high manganese steel embed the high wear resistant with stiffener into metal matrix. The original work hardening of high manganese steel impact resistance performance is remaining, meanwhile the wear resistance strength of high manganese steel ceramic composite

Applications:

Widely used in mining industry, metallurgical industry, construction industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, sandstone and so on.

Product Benefits:

Compared with the general market products, our products smooth surface, accurate dimensions , high wear resistance and longer life. Direct sales by the company foundry, cost-effective products.

Compared with the general Hign Manganese steel cone/mantle, High Manganese steel ceramic composite Mantle /cone Used life can be more than 100% longer.

HOT-SALE PRODUCT

Quality First, Safety Guaranteed